2024 IRG-1: Interplay of chemistry and structure in complex concentrated alloys

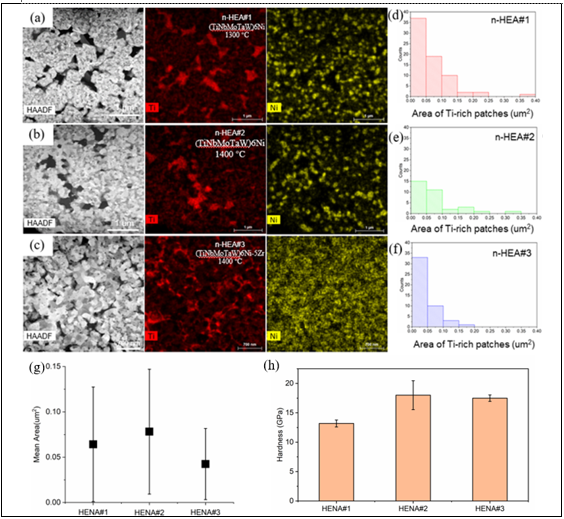

By increasing the sintering temperature to 1400 °C, the microstructure and chemical distribution of the HENA is significantly optimized. (Fig.1a-b, d-e)

By introducing additive Zr into the HENA (sintered at 1400 °C), the microstructure and the compositional inhomogeneity can be further altered. (Fig.1b-c, e-f)

Statistical microhardness tests show that by increasing the sintering temperature or adding additive Zr, the hardness of the alloy can be enhanced. (Fig.1g-h)

Compositional inhomogeneity can be effectively alleviated with increased sintering temperature and elemental alloying/doping.

Tuning compositional inhomogeneity contributes to the hardness enhancement in HENAs.

•Collaborating with Prof.Luo’s group for the preparation and polish of samples.

•Collaborating with Prof. Rupert’s group for molecular dynamics calculations.

C. Wang, M. Qin, T. Lei, L. Wan, S. Shivakumar, K. Kisslinger, T.J. Rupert, J. Luo, H.L. Xin. Materials Characterization 207 (2024) 113563. 10.1016/j.matchar.2023.113563