Laboratory for electron and X-ray instrumentation (LEXI)

Laboratory for Electron and X-ray instrumentation (LEXI) was established in 2009. LEXI houses 6 new major instruments together with a full set of sample preparation equipment and provides strong capabilities for sub-nanometer surface imaging, cross-section imaging, environmental SEM imaging, electron back-scattering imaging and diffraction, composition analysis, grain orientation analysis, electron beam, and ion beam lithography, nano-scale electrical probing, crystal structure determination, texture study, phase transformation study, MEMS in-plane and out-plane vibration study and various metal depositions.

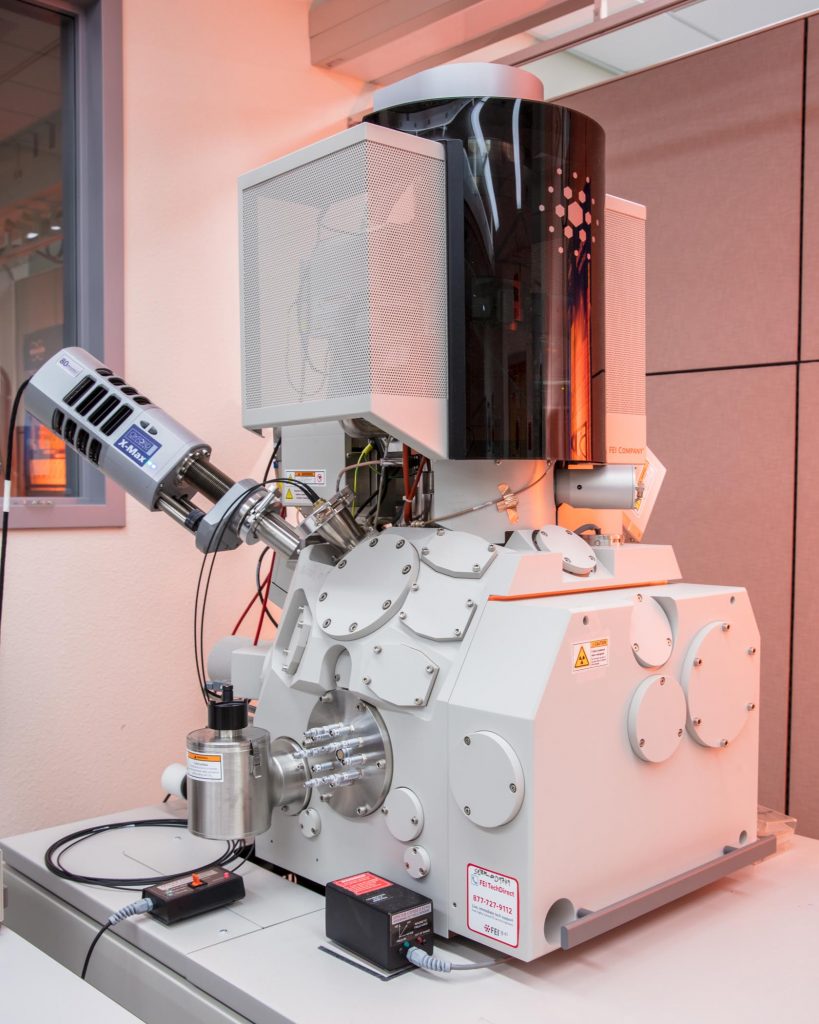

The FEI Magellan 400 SEM is an extremely high resolution scanning electron microscope equipped with a new monochromated electron column, beam deceleration, in-lens secondary electron detector, both in-lens and retractable back-scattering electron detectors, STEM detectors, electron beam lithography package, large EDS detector, in-situ 4-probe system, and in-chamber plasma cleaner. This SEM enables sub-nanometer resolution and high surface sensitivity at low landing energies and is capable of light element analysis, fast elemental mapping, electron beam lithography, low voltage (15-30kV) STEM, and nano-scale electrical measurement.

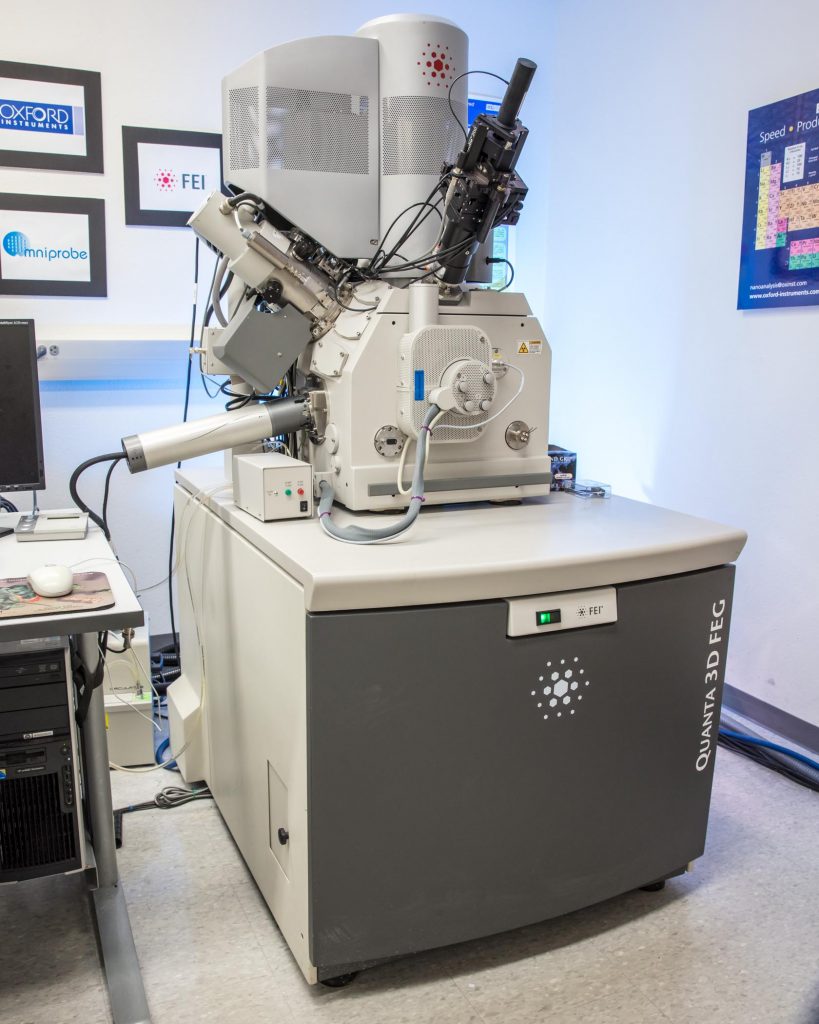

The FEI Quanta 3D FEG is a dual-beam (SEM/FIB) instrument with different imaging modes. It is equipped with an EDS system, EBSD system, cooling stage, beam-deceleration, OMNI probe, and Pt gas injection system. It is capable of high-resolution surface imaging (1nm resolution at 30kV), fast composition analysis, crystal structure determination, orientation mapping, micromachining, ion beam lithography, Pt deposition, and TEM specimen preparation. It may be operated under different vacuum modes, for example, high vacuum, low vacuum, and environmental (ESEM). Either dry inorganic samples or hydrated biological samples can be observed in this instrument.

The Rigaku SmartLab is the state of the art highly automated, fully modular, multipurpose X-ray diffractometer. This fully-loaded system features a 2.2 kW Cu tube and a high-resolution closed-loop theta-theta vertical goniometer with a horizontal sample stage and a 6-position automatic sample changer. Rigaku’s patented cross beam optics (CBO) allows rapid switching between parafocusing geometry for powder samples and parallel beam geometry for thin films and epilayers. The system incorporates SAXS optics for measuring structures with d-spacings up to 100 nm in either transmission (spinning capillary) or reflection (GISAXS) mode. A CBO-f polycapillary optics attachment is available to create a high-intensity point focus of 100 microns for micro-diffraction experiments. An in-plane diffraction attachment provides an additional detector scanning axis orthogonal to the theta/2-theta diffraction plane to allow the measurement of lattice planes perpendicular to the sample surface (e.g., in-plane reciprocal space maps and full pole figures). Four incident beam monochromators {Ge(220) 2-bounce, Ge(220) 4-bounce, Ge(400) 2-bounce, Ge(440) 4-bounce} and two analyzer monochromators {Ge(220) 2-bounce and Ge(400) 2-bounce} enable medium and high resolution X-ray diffraction and reflectivity measurements of highly perfect crystals, epilayers, and multilayer samples with up to 5 arc second resolution. The system’s Anton Paar DHS domed hot stage can be used for in situ measurements of samples in a vacuum, air, or inert gas up to 1100°C. A second furnace stage offers in situ capability in a vacuum, air, or inert gas up to 1400°C. The SmartLab is outfitted with three detectors for maximum versatility and speed: a point scintillator, a 1D D/teX Ultra high-speed silicon strip detector, and a 2D CMOS Pilatus area detector (module size: 83.8 × 33.5 mm²). The most novel feature of Smartlab is the control software, called “Smartlab Guidance.” It can provide an intelligent interface to guide users to select optimal hardware configurations and provides fully automated optics alignment, sample alignment, slit and scan condition settings, and measurements, which helps to minimize the time-to-results for all users.

The Rigaku Ultima III is a versatile X-ray diffraction system equipped with a high precision horizontal sample stage and a cross beam optics system to permit either a high-resolution parallel beam with a motor controlled multilayer mirror or Bragg-Brentano para-focusing beam The Ultima can perform high throughput material analysis and discovery tasks by combining an automatic sample exchanger (ASC-10) with a high-performance one-dimensional D/teX Ultra detector that provides up to 100x intensity gain compared to conventional 0D scintillation counters. Curved/flat graphite and germanium crystal monochromators are available for high-resolution XRD measurements. An in-plane arm maximizes the system configuration options for a wide range of measurements.

Angstrom Engineering EvoVac glovebox-integrated thermal and electron beam evaporator is capable of depositing planar and nano/microstructured thin films of a wide range of materials, including metals, oxides, and organics.